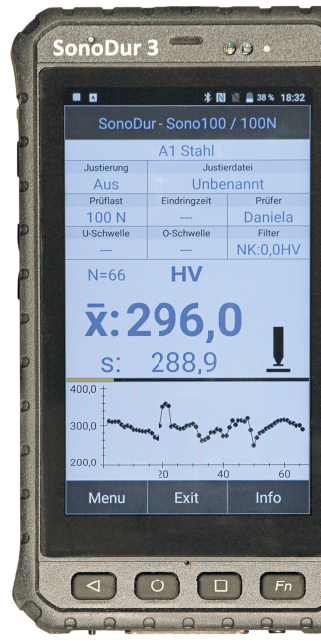

- NewSonic SonoDur 3

详细信息

品牌:NewSonic 型号:SonoDur 3 加工定制:否 测量范围:10 – 1999 NV 产品类型:超声波硬度计 试验力:100 N 允许最大高度:164x86x23 mm 重量:0.37 kg NewSonic SonoDur 3

The New UCI Generation after SonoDur2

Mobile Hardness testing onmetals with UCI * in productionand maintenance. Starting withgoods income inspection untilthe fi nal product is reached.

*Ultrasonic Contact Impedance

Norms: ASTM A 1038 and DIN 50159-1, 2

Conversions: ASTM E 140-13, EN ISO 18265

Multiple Solutions for theSonoDur Family and also forMIC10/MIC20 (by probe retrofi t) Motor probes (HV 0,1 – HV 0,8): 0.1 kgf, 0.3 kgf, 0.8 kgf

Handheld probes (HV 1 – HV 10): 1 kgf, 3kgf, 5 kgf, 10 kgf

The better Way to Hardness Testing

Rugged, easy to use, fast and precise. Made in Germany.

Instrument Features

• Carrying strap, edge protection, IP65, MIL-810G (vibration, shock, drop)

• Brilliant color display in 5’’, smooth glass shield for easy cleaning

• Direct function access just by touch, intuitive menu control, ideal forMIC10/MIC20 users and others

• No set-up needed at beginning of shift – ready for immediate use Android Operating System and Data Transfer

• USB: transfer of measurement data in txt-format using thefile explorer

• WLAN: automatic transfer of single values, completed data stets

• Bluetooth: manual transfer of a set of measurement data

•“Unlimited”storage capacity for measurement data and settings

Intelligent Management ofMeasurement Data and Settings

• Simple access to data and qualified back-traceableassessment of results

• File names can be predefined, automatic closingof data sets

•“AllMeas”- summarized list of results in storeddata sets

Reliable MeasurementTechnique with long-Term Stability

Efficient working tool, optimized for the

daily needs of the inspector

Unique

Can be calibrated in full according to

DAKKS after DIN 50159-2 (calibration

curve 150 – through 900 HV, diamond,

nominal test force)

NewSonic SonoDur 3

Measuring Specifications

* exceeds DIN 50159, dependent on test load and range (see table below). Specifications are valid for 5 measurements usingVickers reference blocks and according to test conditions given in standard DIN 50159.Measuring principle UCI Method, corresponds to DIN 50159, ASTM A1038 Test indenter Vickers diamond 136° Test loads

Newton scale (1kgf = 9.81 N)Motor probes: 1N (0.1 kgf), 3N (0.3kgf) and 8.6 N (0.9 kgf)

Handheld Probes: 10N (1 kgf), 30N (3kgf), 49N (5kgf), 98N(10kgf), (Other test loads on request)Hardness scales and range

(according to relevant standards), in this casetable A1 respectively T1, T2 (low alloy steel).

Different measuring ranges are valid for othermaterials. When exceeding the limits theconversion range will be extended. The calcu-lated values are highlighted in red besides theoriginal data in HV.

Note:

Conversions are acc. to latest ASTM

E140-12bԐ1(2013) und EN ISO 18265:2014.

Conversions into tensile strength: 98N (10kgf)test load only.Vickers

Brinell

Rockwell

Rockwell

Rockwell

Rockwell

Rockwell 5,6

Rockwell (EN ISO 18265 only)

Rockwell

Knoop (ASTM E140 only)

Shore (ASTM E140 only)

Tensile strengthHV

HB

HRB

HRC

HRE

HRF

HRA

HRD

HR45N

HK

HS

MPa10 – 1999 (9999)

76 – 618

41 – 105

20,3 – 68

70 – 108,5

82,6 – 115,1

60,7 – 8

40,3 – 76,9

19,9 – 75,4

87 – 920

34,2 – 97,3

255 – 2180Measurement uncertainty* < 4 % (HV5, HV 10). For other test loads and ranges see table below. Relative repeatability* < 5 % (HV5, HV 10). For other test loads and ranges see table below.

Hardness

scaleMeasurement uncertainty [%] Relative repeatability [%] < 250 HV 250 HV - 500HV 500 HV - 800 HV > 800 HV < 250 HV > 250 HV HV 0,1 5 6 7 8 8 6 HV 0,3 5 6 7 8 8 6 HV 0,8 4 4 5 6 8 6 HV 1 4 4 5 6 8 6

Mechanical and Environmental (Instrument and probe)

Operating time >10 hours in measurement operation (depending on system performance,temperature and instrument settings), up to 8 hours continuous operation, quick exchangeable battery pack (3.7V 3900mAh LiPolymer) Operating Temperature Probe: 0°C to ~ +45°C

Instrument: -10° ~ +50°C // Charging +10°C ~ +40°CStorage Temperature -20°C ~ +70°C Humidity Max. 90%, non-condensing Dimensions Instrument ca. 164x86x23 mm, Motor probe Ø38mm, L=190 mm

Handheld probe Ø25 mm, L=176 mm (free length of rod ca. 12,5 mm)

Handheld probe Ø25 mm, L=207 mm (free length rod ca. 43 mm)Weight Instrument ca. 320 gr (incl. battery pack)

Handheld probe ca. 280 gr, Motor probe ca. 370 gr

Instrument

Processor and Memory ARM ® Cortex™-A53 Octa Core 1.3 GHz / System 2GB RAM /

storage me mory 16 GB eMMC / Micro SD card 4 GB (up to 32 GB )Operating system Android 5.1 (Android 7.0) Keypad 4 function keys, system touch keyboard Power Main battery: 3,7V / 3900mAh, LiPo hard pack, quick exchange

Charging time: <3h to 80% capacity (Instrument off)

Shelf Hours: Up to 6 months

AC Power supply/charger: 90V to 264VAC 50/60Hz to 5VDCDisplay 5“ sunlight readable multi touch display (1280x720 pixel),

LED-backlight (500 Cd/m2), adjustableInterfaces Jack for 5VDC operating/ charging |Docking connector (charging)

USB 2.0 Micro USB (PC) / probe connector Lemo 4 pos.

Micro SD-card 4 GB (up to 32 GB) | 2x SIM card

WLAN 802.11 a/b/g/n | WCDMA/HSDAP/HSPUA, FDD-LTE / TDD-LTE) |

GSM/GPRS/EDGE (b2/b3/b5/b8 | GPS / AGPS / GLONASS

Bluetooth 4.0 (supports BLE mode) | NFC | Speaker, microphoneSensors / Camera / LED Light sensor, G-sensor, proximity sensor, rear camera 8 mega-pixel,

multicolor status LEDIP-Proof IP65 according IEC 60529 Edition 2.1:2001-02 Drop test MIL-STD-810G Methode 516.6, 4 ft. Shock Test MIL-STD-810G Methode 516.6 Prozedur I Vibration Test MIL-STD-810G Methode 514.6 Prozedur I Instrument Language D, EN, IT, FR, SP, PL, CZ, CN - more on request

NewSonic SonoDur 3

Scope of delivery

SonoDur3, Hardness Tester with Data Logger and Data Export, Data Transfer to PC (USB, WLANor Bluetooth resp.), incl. SONO3-NG, Power Source, SONO2-NG/USB USB-Cable, SONO2-HM, ca. 1,5 mProbe Connection Cable, SONO3-TK-1, Transportation Case, SONO-CD, Product-USB-Stick, SONO3Protect, Protection Foils

Mandatory accessory

Motor probe or handheld probe respectively

Other accessories

Reference blocks (MPA, company certificate),test stands, guiding harnesses, auxiliary SW.

Example for configurations -

-

深圳市泰立仪器仪表有限公司咨询热线

深圳市泰立仪器仪表有限公司咨询热线13662293689

深圳市泰立仪器仪表有限公司 电话:0755-83981822/82513866 手机:13662293689 地址: 深圳市龙岗区龙翔大道9009号珠江广场A2栋13D室内容声明:谷瀑为第三方平台及互联网信息服务提供者,谷瀑(含网站、客户端等)所展示的商品/服务的标题、价格、详情等信息内容系由店铺经营者发布,其真实性、准确性和合法性均由店铺经营者负责。谷瀑提醒您购买商品/服务前注意谨慎核实,如您对商品/服务的标题、价格、详情等任何信息有任何疑问的,请在购买前通过谷瀑与店铺经营者沟通确认;谷瀑上存在海量店铺,如您发现店铺内有任何违法/侵权信息,请在谷瀑首页底栏投诉通道进行投诉。

扫一扫,手机浏览

扫一扫,手机浏览